Advantages

Achieves high precision positioning even in a narrow space

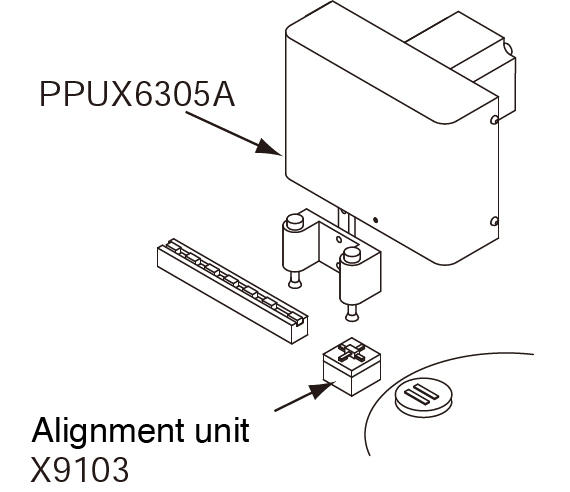

Workpiece positioning is an essential part of automated assembly. In particular, it is essential to use a mechanism that is assembled precisely with precise parts to position a minute workpiece.

Times are moving so rapidly that it is becoming difficult to take the time to create a precise alignment from scratch. Further, as the product cycle of workpieces becomes shorter, it is often impossible to respond to model changes using an air actuator, and it has become difficult to achieve long-term stable positioning even with high-speed operation, as the need for space-saving and high-speed equipment increases. We tackled this problem while manufacturing an automatic assembly system and created an alignment unit that achieves high-speed and high-precision positioning based on years of cam manufacturing technology and high-precision part processing technology. Use MEG’s alignment for automated assembly systems and other FA projects.

Type

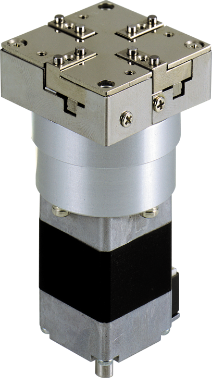

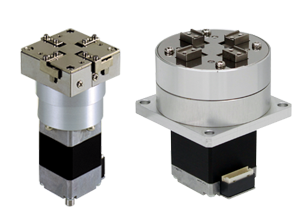

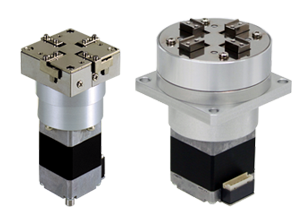

Rigid type

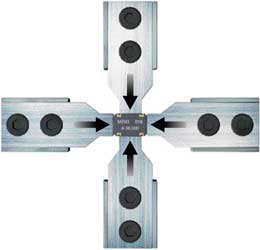

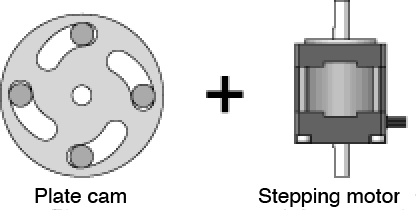

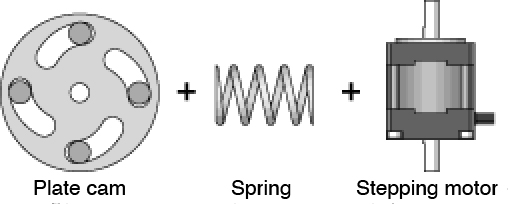

This product was developed for the purpose of positioning while providing clearance. A mechanism for centering delicate workpieces by pulling them in from four directions. It is an alignment with a high-precision and robust design that applies the technology of precise cams.

Buffer type

This product is designed to clamp and position a workpiece under a light load. A unique buffer mechanism has been added to the rigid type, and the workpiece is moved from four directions for centering buffering. This alignment is gentle on workpieces while maintaining the concept of high speed and durability.

Springback during workpiece engagement (centering buffer)

Four fingers are always synchronized.

Motor-driven opening/closing, spring buffer is effective only on the closed side.

Application

Positioning at an intermediate station